What Are Baghouse Filters & How Do They Work?

Baghouse Filters & How They Work

Dust collection systems are a vital part of maintaining a safe working environment for your employees, protecting your equipment, and ensuring compliance with government regulations. At FabCo Industrial Services, we understand the importance of these systems. This is why we specialize in providing several types of high-quality baghouse filters.

Baghouse filters stand out for their efficiency and cost-effectiveness. Our baghouse filters not only safeguard your facility but also contribute to public safety by reducing the amount of particulate matter released into the atmosphere.

In addition to providing new filters, FabCo can refurbish and reuse your existing filter bags, saving you money and reducing landfill waste.

What are Baghouse Filters?

Also known as ‘socks,’ bag filters, or fabric filters, baghouse filters are highly efficient and cost-effective air pollution control devices used in various manufacturing plants. They filter out particulate matter and dust from an incoming airstream using a fabric filtration system.

Depending on the system, a baghouse can house anywhere from six to hundreds of filter bags.

Different Parts of a Baghouse Dust Collector

Each baghouse dust collector is uniquely designed based on its manufacturer and specific application. However, most systems include the following components:

- Fan: The industrial fan is the heart of the baghouse system, pulling contaminated air into the system through an air inlet.

- Air Inlet and Air Outlet: The air inlet introduces dirty air into the filter bags, while the air outlet expels clean air back into the facility or atmosphere.

- Filter Media: The filter media, constructed from various materials depending on the particulates being collected, captures and retains dust. FabCo specializes in cleaning and refurbishing these filters multiple times. This helps to extend their life and reducing costs.

- Filter Cage: The filter cage’s functionality is to support the filter bags, keeping them open for the airstream to pass through.

- Collection Hopper: The collection hopper gathers dust and contaminants, which are then emptied through the discharge unit. Some hoppers have vibration plates to assist in moving dirt to the discharge unit.

- Discharge Unit: The discharge unit empties the hopper of collected dust. Depending on the size of the baghouse, this can be a simple drawer or a more complex system like rotary airlock valves or a double dump device.

Types of Baghouse Filters

There are three main types of baghouse filters, each with unique features and benefits – shaker filters, reverse air filters, and pulse jet filters.

If you aren’t 100% certain which type of baghouse filter you need, contact the FabCo team today! Give us a call at (800) 473-5251 or contact us online here.

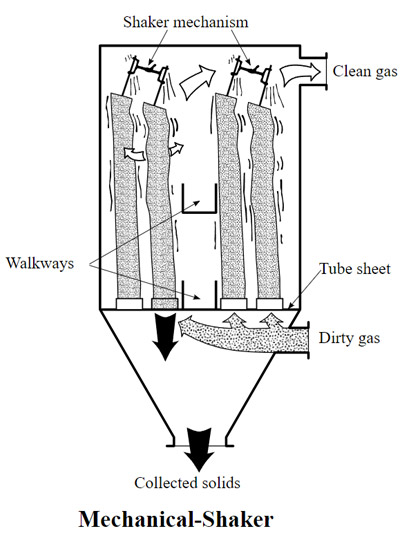

Shaker Filters

Shaker fabric filter collectors are among the simplest and most effective designs, utilizing mechanical shaking to dislodge dust from the filter bags. Despite their simplicity, these filters require more maintenance and space compared to other types.

The shaking mechanism ensures a thorough cleaning of the filter bags, but it does require periodic downtime for the cleaning process to take place. This type of baghouse is often favored for its straightforward operation and reliability, though the need for ample physical space and higher maintenance efforts can be seen as drawbacks.

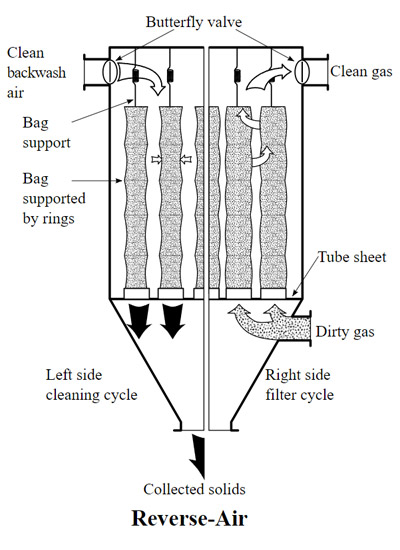

Reverse Air Filters

Reverse air fabric filter collectors operate using a different mechanism. Instead of mechanical shaking, they employ a reverse airflow to clean the filter bags. This reverse air movement causes the collected dust to dislodge from the filter bags and fall into the hopper below. While effective, these filters also demand considerable space and maintenance.

The cleaning process requires stopping the normal airflow, which can limit the continuous operation. However, their ability to handle large volumes of dust and their suitability for various industrial applications make them a viable choice in many scenarios.

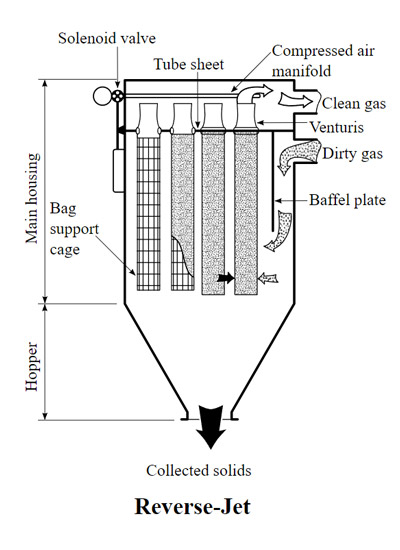

Pulse Jet / Reverse Pulse Filters

Pulse jet (or reverse pulse fabric filter collectors) represent the most advanced type of baghouse filters. They are highly efficient and require less space due to their high air-to-cloth ratio. The cleaning process involves short bursts of compressed air directed into the filter bags. This pulse of air creates a shockwave that dislodges the dust, allowing for continuous operation without needing to halt the airflow.

This capability make pulse jet filters a popular choice in industries where space is at a premium and high filtration efficiency is required. Despite their higher initial cost, the benefits of less maintenance and better efficiency outweigh the investment.

Types of Baghouse Filter Media

The choice of filter media depends on the specific application and the type of contaminants being filtered.

Let’s go over all the options for filter media, as well as their applications:

Woven Filters

Woven filters are commonly used in shaker and reverse air baghouses. These filters consist of tightly woven fibers that effectively capture small particles. The weaving technique ensures a durable filter with a precise pore size distribution, making them suitable for capturing a wide range of particulate sizes.

Their robust construction allows for repeated cleaning cycles, maintaining filtration efficiency over extended periods.

Nonwoven Filters

Nonwoven filters, are best suited for capturing fine contaminants, aerosols, and dust. These filters are created by bonding fibers mechanically or chemically, resulting in a structure with a high capacity for holding fine particles.

The nonwoven design allows for a higher dust-loading capacity and better efficiency in capturing smaller particles, making them ideal for applications where fine particulate matter is a concern.

Related: Increasing Your Baghouse Capacity Strategies and Best Practices

Pleated Filters

Pleated filters are an excellent choice for industries where space is limited but high filtration efficiency is required. These filters provide a high filtration efficiency with a lower air-to-fabric ratio. The pleated design increases the surface area available for filtration, allowing for greater dust capture without increasing the size of the baghouse.

Pleated filter bags offer another level of efficiency with their larger surface area. Contact FabCo for more information on pleated filters.

Felted Filters

Felted filter bags are designed to trap particles through impact and interception. These filters provide extensive target space for capturing matter, making them highly effective for a variety of applications. The felted structure enhances the filter’s ability to capture and retain particles, ensuring a high level of filtration performance.

Felted filter media is particularly useful in environments with high dust loads or where the particulate matter has a variety of sizes and shapes.

Polyester Filters

Polyester filters are renowned for their resistance to abrasion and dry heat, making them a versatile option for various industrial applications. Their robust construction ensures durability and longevity, even in challenging environments.

These filters are particularly effective in capturing a wide range of particulate matter, maintaining their integrity and performance over extended periods of use.

Nylon Filters

Nylon filters excel in environments where abrasion resistance is essential. They are ideal for filtering alkali compounds, but are not suitable for high-temperature applications.

The durability and effectiveness of nylon filters make them a preferred choice in industries dealing with alkali substances.

Teflon Filters

Teflon filters are well-suited for high-temperature environments, thanks to their exceptional resistance to both chemicals and abrasion. These filters maintain their performance and structural integrity even under extreme heat and chemical exposure, making them an excellent choice for demanding industrial processes.

PTFE Tetratex Filters

PTFE Tetratex filters are designed for environments with high concentrations of acids and alkalis. Their unique construction provides reliable filtration in harsh chemical conditions. With PTFE Tetratex filters, you get all the benefits of excellent performance and longevity.

These filters are particularly suited for applications where there are high concentrations of acids and alkalis. Contact FabCo for more information on whether PTFE Tetratex filters are the right fit for your environment.

Fibreglass Filters

Lastly, fibreglass filters are designed for use in environments with high acid concentrations. They offer excellent filtration performance under these conditions but should not be used where cyanides or chlorides are present.

The specialized nature of fibreglass filters makes them a valuable asset in specific industrial settings where acid resistance is required.

Related: Things You Should Know About Baghouse Filter Media

How Do Baghouse Filters Work?

Now that you have a better idea of all the filter options available to you, let’s go over how baghouse filters work.

When contaminated air enters the baghouse through the inlet, it flows through the filters, where dust collects on the filter surfaces. This collected dust, known as the “cake,” helps trap additional particles. The cleaning cycle starts when air pressure drops, dislodging the dust cake and allowing it to fall into the hopper. The cleaned air then exits through the outlet.

Materials Filtered by Baghouse Filters

Baghouse systems effectively filter various materials, including:

- Grain dust

- Wood fibers

- Asphalt

- Cement factory dust

- Silica dust

Applications of Baghouse Filters

Baghouse filters are used across multiple industries, including:

- Aggregate processing plants

- Woodworking facilities

- Food processing and grain production

- Pulp, paper, and packaging industries

- Metal mills

- Ceramics and building materials

- Power plants

- Pharmaceutical manufacturing

- Chemical production

Factors Affecting Baghouse Performance

There are a couple factors which influence the performance of baghouse systems:

- Filter Media: The type of filter media used must match the conditions of the environment, such as temperature and chemical exposure.

- Cleaning Frequency: Regular cleaning maintains filter permeability, but excessive cleaning can reduce the filter’s ability to trap particles by removing the dust cake.

Have questions on your baghouse filters’ performance? Please don’t hesitate to contact our team today at (800) 473-5251 or by email at sales@fabcoind.com.

Contact FabCo for Baghouse Filters!

Installing a baghouse filter system from FabCo Industrial Services ensures a cleaner, safer working environment, compliance with regulations, and efficient operation. By choosing the right filter media and maintaining proper cleaning cycles, you can optimize your dust collection system’s performance while protecting the environment and your employees’ health.

Need a baghouse changeout/replacement service? Please contact our team at (800) 473-5251 today.